3D printing has gained tremendous popularity in recent years. This has also made 3D printing more accessible to both businesses and individuals. As a result, there are many 3D printing techniques to choose from. In this blog we will look at the different printing techniques and their possibilities.

The different 3D printing techniques:

- Fused Deposition Modeling

- Selective Laser Sintering

- Stereolithography printing

- Low Force Stereolithography

- Laminated Object Manufacturing

- Inkjet technology

Are you also interested in using a 3D printer to turn your idea into reality? We are happy to assist you. Feel free to drink a cup of coffee with us to discuss the possibilities.

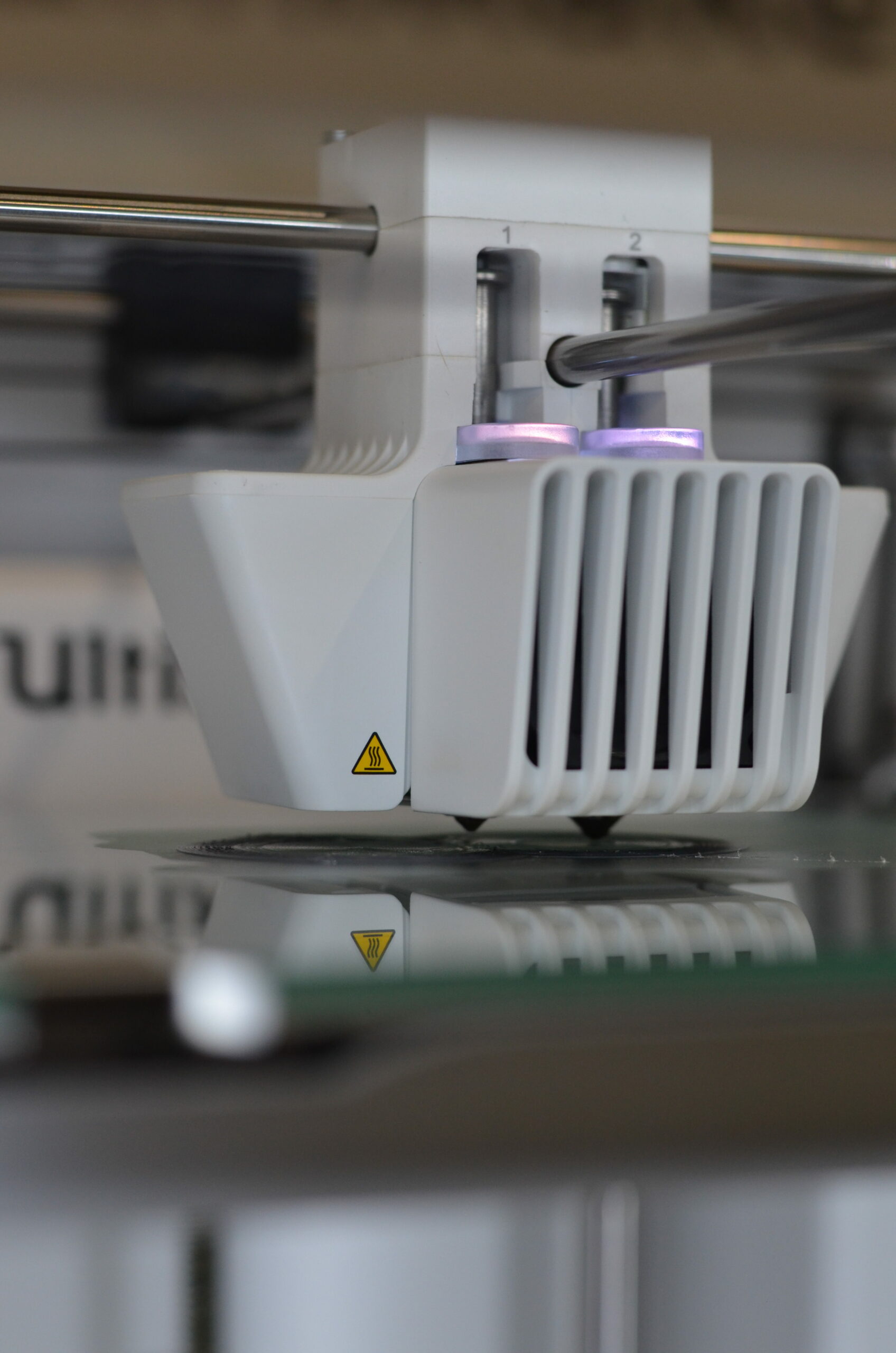

Fused Deposition Modeling (FDM)

This kind of technic is the one that we all know, these printers use different kind of plastic filament, which will be heated till it’s melt and extrude layer to layer. There are different kind of filament that you can use, the type of plastics depends on the functionality of your 3D product that you want to print.

Selective Laser Sintering (SLS)

By using a laser in a powder bed the temperature will set to above melting point. Layer after layer will result in a 3D product. With this kind of technic you don’t need any support to print your product. This technic uses a technical functional plastic for example nylon. You will always need to follow up with an after treatment to make a smooth surface.

Stereolithography printing (SLA)

In a liquid bath with UV-sensitive liquid an UV laser will harden up your 3D product. This technic is very precisely and almost achieves the characteristics of an ABS plastic. When a layer is finished the object will be moved 1 millimeter downwards in to the basin. Your product is attached on a platform. This kind of 3D printing is very fast and the surface is very detailed and complex geometries are not a challenge. The variety of sizes depends on the 3D printer.

Low Force Stereolithography (LFS)

LFS is almost similar as SLA printing. LFS uses a liquid and linear illumination to print your product. LFS uses a Light Processing Unit with a resin tank, optical window and rollers. A flexible film bows gradually as the part is lowered, reducing pressure and allowing for light-touch supports that can be easily peeled away.

Laminated Object Manufacturing (LOM)

This technic is almost similar to SLS, in case of powder you use paper or layers of plastics or metal (laminated) in combination with heat and pressure. A computer controlled laser or blade will cut the shape of your 3D product.

Inkjet technology

The most important difference to use inkjet technology is the high end quality that you get and print directly in all colors. With this technic it don’t melt the powder but glue the material. Most common example of this technic is the 3D printed products of yourself “mini me’s”.

The variety of sizes that can print on 3D printers depends on the 3D printer also the time that it tooks to print your 3D product depends on your design, the size of your product and what kind of surface you want, and also the amount of your 3D printed parts.

3D printing at Beeliners

Do you want to develop your idea in cooperation with Beeliners and do you need a 3D printer for that? We would love to help you out! Feel free to drop by for a cup of coffee and we will be happy to discuss the possibilities with you.